Additional Pump Series

The following series are make-to-order products. To learn more about these pumps and to get quotes, please contact us.

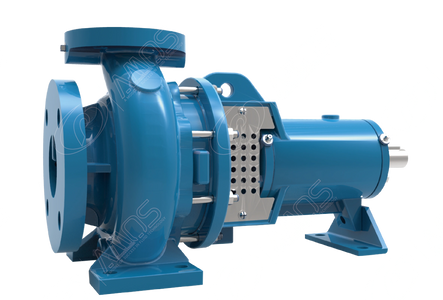

MCE Series

MCE Series

MCE Series

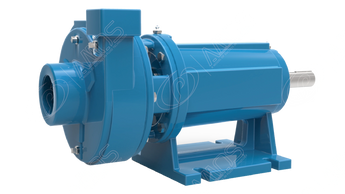

MCE series pump is reliable End Suction Pump manufactured to the international standard EN733/DIN24255, with American system unit. Compared with MCA series pump, it has the same standard and the common impeller, casing cover and frame with same technology process and functions. It allows full interchangeability. MCE series pump is connected with standard NEMA motor by ANSI standard flange. This line pump are featured with high efficiency and energy saving. Products are widely used in regional heating, general water supply, air conditioning, refrigeration plant, industry, fire fighting and environmental engineering.

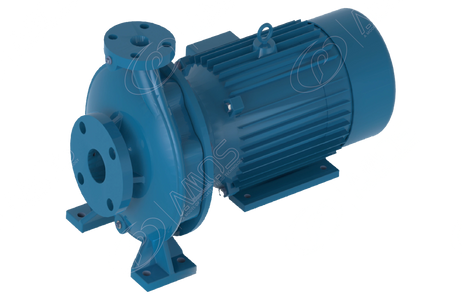

MCF Series

MCE Series

MCE Series

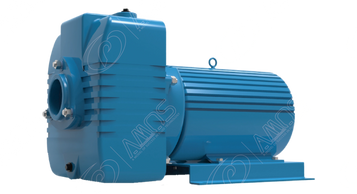

MCF series pump is horizontal end suction, well designed volute type casing, foot mounted monoblock centrifugal pump with compact & sturdy structure. It is built for greater operating efficiency and economy. Volute casing and enclosed impellers are designed to give the best possible hydraulic efficiency and good suction lift. As the impeller is mounted on extended shaft of motor, alignment problem is completely eliminated. Standard ANSI flange mounted with standard NEMA JM motor available from any electric motor manufacturers. This series pump also has Back Pull Out design the same as our other end suction series. Dynamically balanced rotor ensures vibration and noise free operations, increase the bearing and seal life.

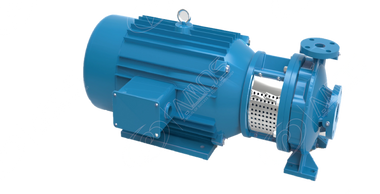

MCFA Series

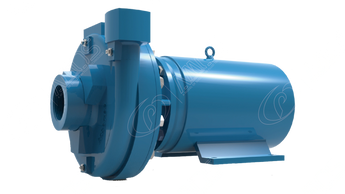

MCP-CC Series

MCP-CC Series

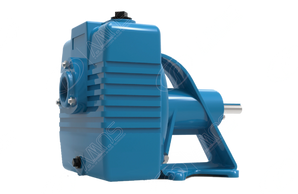

MCFA series pump is horizontal end suction, well designed volute type casing, foot mounted close coupled motor pump with compact & sturdy structure. It is built for greater operating efficiency and economy. Volute casing and enclosed impellers are designed to give the best possible hydraulic efficiency and good suction lift. Standard ANSI flange mounted with standard NEMA EPACT C face electric motor available from any electric motor manufacturers. As the impeller is mounted on a stub shaft fitted onto motor shaft, alignment problem is completely eliminated.This series pump also has Back Pull Out design the same as our other end suction series. Dynamically balanced rotor ensures vibration and noise free operations, increase the bearing and seal life.

MCP-CC Series

MCP-CC Series

MCP-CC Series

MCP-CC series close coupled end suction pumps. They are suitable for regional heating, general water supply, industry, etc. The close coupled pump is directly mounted to a JM motors. As the impeller is mounted on extended shaft of motor, alignment problem is completely eliminated. The enclosed impeller ensure the highest efficiency, and is hydraulically balanced with reduces axial thrust, and increases bearing life. Bronze wear rings are easily replaced and prevent casing wear.

MCP-FM Series

MCP-CC Series

MCP-FM Series

MCP-FM series end suction pumps are frame mounted pump. They are suitable for regional heating, general water supply, industry, etc. Back pull-out design allows maintenance of bearing frame without disturbing the suction and discharge piping. Eight casing discharge positions are possible. The enclosed impeller ensures the highest efficiency. The impeller is hydraulically balanced, which reduces axial thrust and increase bearing life. Bronze wear rings are easily replaced and prevent casing wear.

MCV Series

MCV Series

MCV Series

A good choice for marine as well as municipal and industrial applications, these close-coupled electric drive pumps are available in five models. Features include: rugged class 30 cast iron construction; open trash-type impellers; stainless steel pump shafts with carbon/ceramic mechanical seal faces; and NPT female suction/discharge ports. NEMA L single phase and NEMA B three phase motors are offered in 1-1/2 hp through 15 hp sizes. Standard motors for 2" and 3" pumps can be selected to meet design criteria for Marine Duty per USCG259 and AIEEE-45, 122˚F ambient. Capacities to 400 GPM and heads to 188 ft.

MCW Series

MCV Series

MCV Series

MCW series frame-mounted self-priming centrifugal pumps are designed for marine, municipal and industrial applications. An economical pump for circulation or transfer service, 1-1/2” , 2” and 3” industrial pumps are available in class 30 cast iron construction. These pumps offer abrasive wear-resistance due to erosion, and maximum strength for heavy duty applications. These pumps are suitable for engine, electric motor or hydraulic drives, with capacities to 400 GPM and with total dynamic heads to 184 ft.

MCX Series

MCV Series

MCX Series

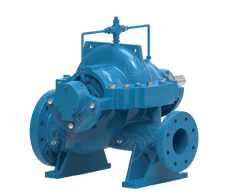

MCX series pumps are single stage, double suction with split casings. They are suitable for pumping unsettled water, clean water, non-drinkable or hydrocarbon at a temperature not exceeded 221°F. Series MCX pump are available for capacities of 68-11000m3/h and head of 7-200m, they are adoptable in water works ,irrigation and drainage pumping station, power station, Indus-trial water supply systems, firefighting systems, marine applications as well as general applications in refineries, etc. In-line new design casing, high performance impeller, service friendly shaft, excellent efficiencies, outstanding NPSH, long-life bearing and application orientated seal (mechanical seal and gland packing).

Copyright © 2020 M&C Pump Americas, LLC - All Rights Reserved